Usutu

- December 2022

Two new MH 2000 ACT HPS Reco ECO kilns have been commissioned in Eswatini. The conversion of heating medium from hot water to steam now allows the Usutu Forest Products Company to run ACT drying processes and achieve faster results.

Forestal Leonera

- November 2022

Forestal Leonera opts for three new Mahild combi chambers of type MH 2000 ACT HPS Reco. Both the high-efficiency impeller PENTAVENT and the heat recovery system ECOVENT DUPLEX are integrated for more efficient and ecological wood drying.

For 2023, the Chilean sawmill places an order for a new steaming kiln.

ForAction Chili

- October 2022

In order to make optimal use of the available steam capacity, ForAction Chili successfully commissions the 6th MAHILD lumber drying kiln. Planning for a new sawmill with three more MAHILD kilns is already underway. These promise an annual volume of ~ 216,000 m³.

Sincol

- October 2022

Sincol invests in the new Mahild UCK technology. With the continuous dryer, the Brazilian door manufacturer can increase its annual production by 35000 - 40,000 m³.

BSW Latvia

- October 2022

BSW Latvia now operates 13 drying chambers of the reinforced MAHILD DUO-FAN series. The 4 new kilns increase the annual volume by approx. 50,000-55,000 m³.

Rothmund

- September 2022

At the saw and planing mill in Klettgau, the construction of two new high-performance kilns has been successfully completed. In addition, all 8 existing lumber dry kilns were equipped with the latest generation of MAHILD control technology. The integrated pulse ventilation system allows Rothmund to reduce power consumption by up to 50%.

Rutishauser

- September 2021

Rutishauser invests in new drying kiln from MAHILD. With a volume of approximately 130m³, the kiln can be used for both softwood and hardwood drying and offers maximum flexibility. The chamber door in two-part design, which can be placed along the chamber side wall, ensures that minimum space requirements are met.

CMPC Mulchen

- July 2021

Successful modernisation: The CMPC sawmill in Mulchen expands its existing drying kilns with the MAHILD ECOVENT DUPLEX system and achieves steam savings of 10%.

Reybosques

- July 2021

Despite the COVID-19 pandemic, two new front loaded kilns started operations in Ecuador today. Due to ongoing travel restrictions, both assembly supervision and commissioning were carried out online. We would like to thank the entire team for their excellent cooperation.

Maderera Piedra del Toro

- March 2021

The foundations have been laid, the prefabricated stainless steel elements have been produced and are on their way to Uruguay -- where a new Mahild UHT-TMT chamber will go into operation in 2021.

Rettenmeier Holzindustrie

- March 2021

As part of the construction of a new high-performance sawing line at the Wilburgstetten site, Rettenmeier is investing in 2 Mahild high-performance lumber dry kilns of the CONTRAFLOW type.

The 75m and 100m long continuous kiln will be equipped with new PENTAVENT high-efficiency fan impellers and achieve a total annual volume of 400,000 m³.

Todesmade

- December 2020

Brazil's largest furniture manufacturer invests in 4 ACT kilns with an annual volume of 125,000m³.

Costa Iberica

- December 2019

New plant type CFX goes into operation. With these continuous kilns, Costa Iberica replaces the existing conventional kilns and reaches an annual volume of approx. 1,890,000 pallets.

Maderas Hermanos Castro

- December 2018

Maderas Hermanos Castro invests in the kiln type TMT-40 for thermal lumber modification.

Forestal Andes

- August 2018

After a successful project in 2016, Forestal Andes buys again from Mahild. 4 kilns of the type MH2000 ACT ECOVENT DUPLEX increase the production by another 60.000m³.

Pfeifer Uelzen

- June 2018

Commissioning of the first CONTRAFLOW plant in Europe: After Australia, Tasmania, New Zealand, Argentina, Brazil and China, the first CONTRAFLOW kiln in Germany is going into operation. This will expand the drying capacity of lateral lumber at Pfeifer Uelzen by 70,000 m³ per year. The plant type MH2000 CF LT combines low and high temperatures from flue gas condensation.

Blocks & Cutstock

- February 2018

Block & Cutstock was convinced by the Mahild technology purchased in 2016. They invest in two more ACT drying chambers with ECOVENT DUPLEX system and increase the production by 55.000m³.

Timberlink Tarpeena

- February 2018

At Timberlink Tarpeena, another conversion of existing ACT to CONTRAFLOW kilns is being carried out. The result is impressive:

- 50% increase in production

- 30% savings in thermal energy consumption

- 11% savings in electrical energy consumption.

Bagaro Maderas

- February 2017

After the development, installation and testing of the new PENTAVENT fan impeller, the following successes can be recorded:

- 30% increase in efficiency compared to the previous model

- Bagaro invests additionally in 2 new chambers type MH2000 ACT ECOVENT with front forklift loading

- 25% saving potential by the ECOVENT DUPLEX system.

Timberlink New Zealand

- February 2016

At Timberlink New Zealand, an existing ACT plant is converted to a CONTRAFLOW plant for the first time. The result:

- 50% increase in production

- 30% savings in thermal energy consumption

- 11% savings in electrical energy consumption

- Avoidance of load peaks on the boiler

AKD Softwoods

- November 2015

AKD Softwoods invests in 2 Mahild CONTRAFLOW kilns and reports to the Australasian Timber Magazine about the successes achieved.

Click here for the online edition of Australasian Timber

Siat Braun

- January 2015

Siat invests in the 2nd generation of the MAHILD LUVO system. Due to the high air capacity, short drying times can be achieved despite low temperature drying. With the 4 new chambers Siat increases the annual capacity by 35.000m³.

.

Arauco trains 20 employees in advanced lumber drying

- November 2012

Arauco again relies on MAHILD to train 20 of its employees from different sawmills. Specifically, this involved a course on advanced lumber drying. In total there were 4 days of lessons and the course was attended by the heads of the divisional managers responsible for process improvement and the associated mechanical drying process. The course includes training on various topics that occur in the drying process, such as: application of the Fourier and Heisler equations for heating and cooling, drying time model by convective mass transfer, thermal performance by psychrometric model and thermal energy model.

Arauco

- December 2011

In sawmills Viñales 5 dryers will be installed. There are three tunnels with three fully independent control areas and two front loaded kilns. Designing new concept in recoing reducing considerably the condensation and waste liquids. Also includes system MULTI-HUM. Including the new kilns, the plant will have 11 MAHILD kilns and two RECOS.

Forestal Tromen

- December 2011

Forestal Tromen site Loncoche are installing 5 accelerated MAHILD kiln type tunnel, implemented with ECOVENT system.

CMPC

- December 2011

In sawmills Constitution, CMPC installs 6 accelerated drying of front-loading kilns with hot water heating and equipped with ECOVENT system. In addition they will be first dryers with color cover in Chile.

Arauco trains 30 employees in lumber drying

- November 2011

Arauco, the largest Chilean forestry company chose MAHILD in order to train 30 of their employees from different sawmills. It was a training course for operators of high-tech drying. In total there were 8 days of classes and participating were kiln assistants, operators, supervisors and department heads.

The course included a comprehensive training that involved different topics present in the drying process, such as anatomical knowledge of wood, wood physics, thermodynamics and Psychrometry, heat and moisture transfer, best practices of filleting and charges, schedule creation, degradation and ways to reduce, control system operation, engineering notions of drying, drying of Eucalyptus and thermally modified wood.

The feedback of the participants was very positive and planning was made for an advanced course of drying to be performed by MAHILD in a couple of months.

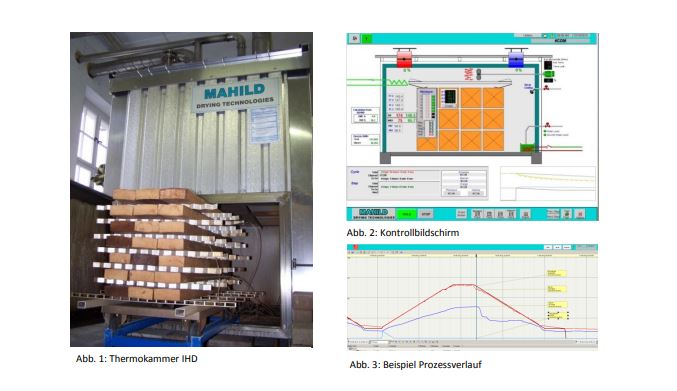

Description of pilot-scale thermo-kiln of IHD

- August 2011

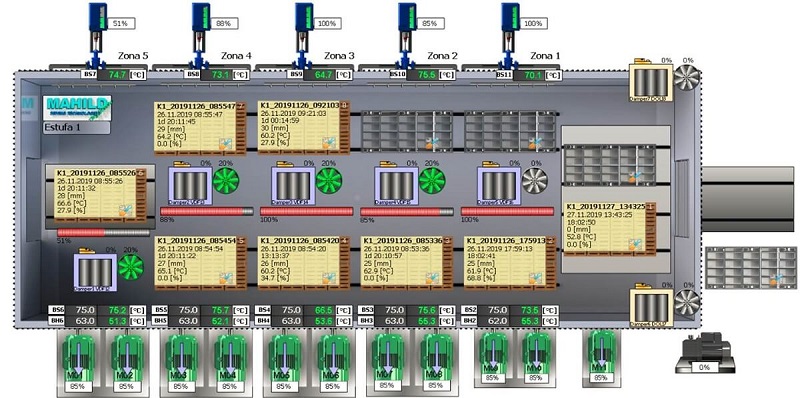

The thermo-kiln of IHD (fig. 1) allows to manufacture thermally modified timber (TMT) in a pilot-plant scale by defined conditions. The kiln of type MAHILD MH 2000 TMT is configured for thermal treatment under normal pressure at temperatures up to 250 °C. For distinct process steps, steam can be added. Staple size is up to 1200 mm length; the usable volume is of about 0.5 m³. The optimal cross-section is 650x650 mm², the maximum 900 mm width and 800 mm height. The kiln can be used as conventional kiln dryer, too, with controlled supply and exhaust air valves. With a special technology, applied for patent in Germany in 2010, it is possible to treat plane materials, like veneers or panels, with a high quality. This kiln is controlled by PC (fig. 2) and SPS with software MM 4000. The process steps and a lot of parameters are freely programmable; a typical run is shown in fig. 3. Control factors for the thermal modification are kiln and wood temperature, respectively, for kiln drying this is air temperature and air humidity. Relative air humidity is measured by psychrometers, the wood moisture by electrical resistance method. The wetting, e. g. for cooling down, is done by water spray. For a uniform flow, the fan can be operated in a forward-reverse mode, controlled by a be frequency converter.

Source:ihd Dresden

Red Stag Timber

- August 2011

A Red Stag Timber em Rotorua encomendou esta semana a primeira câmara de contrafluxo contínuo operacional da Nova Zelândia. A capacidade das câmaras é de 100.000m³ de madeira seca por ano. Em vez dos desenhos e funcionamento mais tradicionais da câmara, o CONTRAFLOW Mahild de 60 metros de via dupla utiliza duas vias dentro da câmara. O calor da pilha de saída quente seca é usado para pré-condicionar a madeira verde que entra na câmara e a umidade da secagem da madeira verde também é usada para recondicionar a madeira seca que sai da câmara.

Esta nova câmara de secagem irá reduzir significativamente a energia necessária para secar a madeira e faz parte do esforço da Red Stag para melhorar a eficiência e a qualidade do produto. O gerente do câmaras de secagem, Steve Goldsmith, diz que está extremamente satisfeito com a qualidade da madeira serrada que sai desta nova câmara Mahild.

James Jones

- February 2011

James Jones & Sons Ltd is investing in a further six kilns from Mahild in a move which will boost annual kilning capacity at its Steven's Croft mill operation at Lockerbie to 160,000m³. The latest move at the site will take the group’s total number of kilns to 16. The new units are expected to come on stream during October and reflect the growing volumes being processed through the new sawline at the Lockerbie 3 mill. Existing kilns at the site are fitted with a heat recovery system and have already successfully reduced energy consumption. The kilning complex is being heated with hot water provided by the neighbouring Eon biomass power plant and conveyed by a pipeline installed in 2010. James Jones said the system saves an estimated 9,000 tonnes of carbon emissions annually.

Mahild reduces drying energy

- July 2009

The key focus for kiln specialist Mahild was its latest developments for cutting energy used in drying timber. The newest technology highlighted was the latest generation of its ECO-VENT system, ECO-VENT III. This uses exhaust air from the kiln to warm incoming air and also captures radiant heat from the unit’s walls and roof, “reducing heat transmission to almost zero”. Heat from electric motor panels, frequency drives and piping is also recovered. “The latest system can save 25-30% of the thermal energy used to dry lumber by conventional technology,” said Mahild’s Lance Vinnell. “For a 200m³ capacity kiln, that’s a CO2 reduction of 650 tonnes a year, equal to the emissions from 130 homes.” He added that as part of its DryGreen initiative Mahild has also developed new energy management control systems. Among Mahild’s latest UK clients are Howie Forest Products and James Jones & Son, with the latter installing its kilns at its new Lockerbie plant.

Dry Green - the future of lumber drying

- December 2008

Introduction of the MAHILD environmental policy by focus of consistent technology for significantly improved environmental performance, with consistently high productivity for the benefit of our environment.

- Reduction of CO2 emissions

- Reduction of the emission of exhausted air

- Reduction of noise

- Reduction of the thermal energy requirement for drying up to about 25%

- Reduction of heat and transmission losses in housing and foundation

- Reduction of electrical energy by variable air flow during drying Intelligent energy management for the optimum use of heat and increased boiler efficiency.

Red Stag Timber

- October 2008

Red Stag Timber has invested in another Mahild high temp kiln. The new kiln will have a capacity of 100,000m³ per annum. Red Stag has ensured the learning from the Mahild installation back in 2006 has been implemented with this installation. We requested Mahild "Guru", Dirk Daniels, to project manage this installation. Local agents, Lyle Engineering, are the contracted installers. Project timelines are running to plan, even with the inclement weather we have experienced. The commissioning date is set for mid-October, 2008.

BSW Sawmills

- August 2008

After careful selection and detailed technical studies from proposals of all renown potential suppliers Mahild was selected to supply and build the additional dry kiln capacity at Fort William mill.

The project includes 10 new all-aluminium dry kilns of a net volume of 200 m³ each and the installation of the most advanced kiln control system, MAHILD MM 4000.

The kilns will be equipped with the MAHILD ECO-VENT II – System to allow recovery of heat from the exhaust system of the dry kilns. The system provides low energy usage especially in winter months and helps to ruduce energy cost.

In addition to this it was also decided to install the MM4000 Energy Management System which allows operators to program product priorities and considers the energy available from heating plants on the site in order to manage best possible productivity and product quality.

Mahild is one of the most experienced kiln manufacturers in the world specialising in high production dry kilns for softwoods. It´s Technology is geared for large scale production of kilns and their components. Today’s manufacturing capacity allows production of 500 kilns per year in various sizes.

GELO Holzwerke

- December 2006

Mahild obtains the third order from GELO Holzwerken. Including this third chamber block, a total of approx. 700m³ drying capacity are available.

CMPC

- August 2006

Two further high-speed drying centres are installed at CMPC in Chile. Drying performance doubles.

Klausner Holz Niedersachsen

- August 2006

Contruction start of 24 large capacity dryers KHN Klausner Holz Niedersachsen.

Red Stag Timber

- June 2006

Red Stag Timber chooses MAHILD UHT technology and changes to three shift drying.